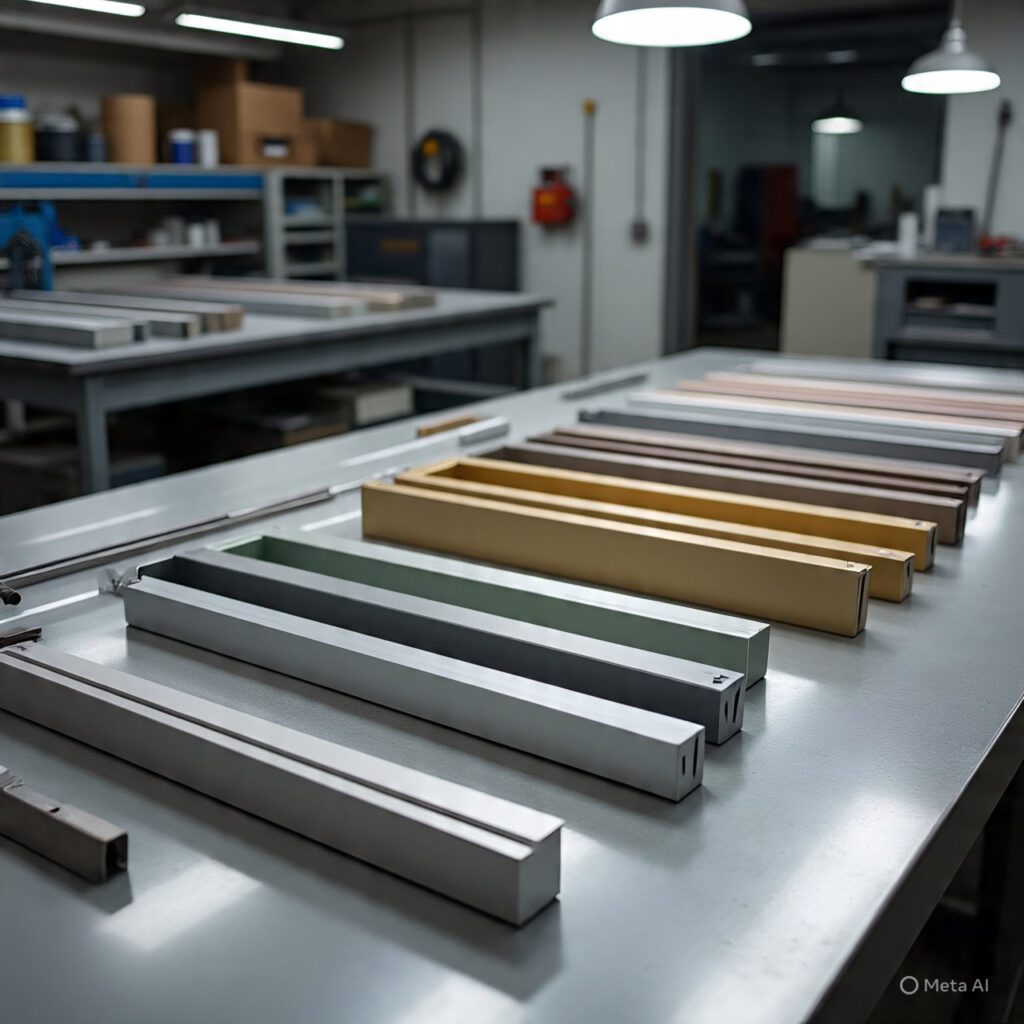

Aluminium Frames

Aluminium frames are a popular choice for modern windows, doors, shopfronts and balustrades. One of the most important considerations for aluminium frame performance — both aesthetic and functional — is the coating or finish. Powder coating is often the preferred finish for its durability, variety, and low maintenance. In this post we set out the powder coating options available for aluminium frames, what to consider, and how Accend Aluminium & Glass leverages these options to deliver high-quality frames in the Roodepoort & Randburg areas.

What is Powder Coating & Why Use It

Powder coating is a dry finishing process: a fine powder (usually of resin, pigment and other additives) is electrostatically applied to cleaned aluminium, then cured under heat. This forms a durable skin that resists corrosion, UV rays, wear and tear much better than many liquid paints. It’s environmentally friendlier (lower volatile organic compounds) and offers more consistent finish, especially for architectural aluminium applications. WELLSTE+3Shapes by Hydro+3ametals.com+3

At Accend Aluminium & Glass, we understand that the finish & coating are a critical part of how long aluminium windows and doors last — among the factors we list as making a frame durable and maintaining performance. Finishes like powder-coating or anodising guard against corrosion, fading, UV exposure, and wear. 2ag.co.za

Main Powder Coating Options & Finishes for Aluminium Frames

When selecting a powder coating finish, consider the environment (e.g. exposure to sun, rain, salt spray), the desired appearance (colour, texture, gloss level), and budget. Below are key types & styles of powder coatings, many of which are available through manufacturers like 2AG.

Thermoset vs Thermoplastic Powders

-

Thermoset powders cure irreversibly, forming chemical cross-links. They tend to have high hardness, chemical resistance and UV stability. Common types include polyester powders (standard & “super-durable”), epoxy/polyester hybrids, polyurethane, and fluoropolymer coatings.

-

Thermoplastic powders melt when heated and solidify on cooling without forming permanent chemical crosslinks. They may be re-melted; often used where thicker coatings or special properties are needed (less common for standard door/window frames). ametals.com+1

Types of Powder Coating Finishes

Below are common finish types, gloss/texture options, and special coatings:

| Finish Type | Characteristics | Where It Excels |

|---|---|---|

| Standard Polyester | Good all-round durability, colour range, cost-effective | Most residential windows/doors |

| Super-Durable Polyester (e.g. “Architectural” grade) | Better fade/UV resistance, longer warranty | Coastal areas, high exposure to sun or weather |

| Polyurethane / Polyurea | Higher chemical/abrasion resistance, smoother finishes | Premium applications, harsh environment, or where sheen and finish quality matter |

| Fluoropolymer / PVDF | Very high UV stability; colours stay vibrant; gloss retention over years | High-end facades or harsh climates (coastal, high altitude) |

| Textured / Matte / Satin / Gloss Finishes | Texture can mask minor surface imperfections; gloss is more striking but shows blemishes more | Depending on design style & preference |

| Special Coatings | Metallics, powder with added hardness, anti-bacterial, coarse textures, or special effects | Boutique designs, commercial storefronts, custom architectural work |

Pre-Treatment & Curing

Before powder coating, aluminium frames must be properly pre-treated: cleaning, degreasing, removal of mill scale, possibly conversion coating (e.g. chromate or non-chromate). Then the powder is applied, and the frame is cured in a high temperature oven. Proper curing is critical for adhesion, durability, and performance. greatdanepowdercoating.com+2WELLSTE+2

Factors to Consider for Roodepoort & Randburg Context

For the areas of Roodepoort, Randburg and surrounding Gauteng, these are practical considerations:

-

Climate & UV Exposure: Gauteng gets strong sunlight; UV fade resistance is important. Super durable polyester or fluoropolymer coatings give better performance under sun.

-

Rain & Humidity: Occasional high rain and humid periods mean coatings must resist corrosion (powder coating helps, but proper sealing and drainage in design matter too).

-

Colour Choices & Trends: Darker colours absorb heat, light colours show dirt more. Depending on architectural style, finishes like charcoal, bronze, white, or metallics are common. Accend’s product line (windows, doors, shopfronts) allows selecting from a range of powder-coated colours. 2ag.co.za+22ag.co.za+2

-

Coastal Proximity: If a project is near the coast (salt spray), need coatings with extra protection: either specially formulated powder coatings or possibly additional protective treatments.

What Accend Aluminium & Glass Offers

At Accend Aluminium & Glass (2AG), we make sure our customers have choices when it comes to aluminium frame finishes:

-

Our Aluminium Doors are described on our site as “available in anodised finish, or in a range of powder coated colours.” 2ag.co.za

-

When clients request Double Glazed Aluminium Windows, we offer customization of frame finishes, colours, or styles. 2ag.co.za

-

In the “How Long Do Aluminium Windows and Doors Last?” page, 2AG mentions finish & coating such as powder-coating and anodising among the key elements in ensuring durability. 2ag.co.za

This means if you order frames from 2AG in Roodepoort or Randburg, you are able to choose among coatings that match both your aesthetic preferences and performance needs.

Typical Lifespans & Maintenance

A well applied powder coating finish on aluminium can last for 15-25 years or more, depending on exposure, colour, and upkeep. Premium finishes (super-durable powders or fluoropolymers) often come with longer warranties.

Maintenance is minimal: gentle cleaning (with mild detergent/water), avoiding harsh abrasives, checking for damage (scratches etc.) and touching up if needed. Superior Paint & Powder Coating+1

Comparisons: Powder Coating vs Anodising & Other Coatings

While powder coating is excellent, there are trade-offs vs other finishes:

-

Anodising: Enhances natural oxide layer; long life; natural metallic look; less variety in colour; potentially more expensive for custom colours.

-

Mill Finish / Untreated Aluminium: Less protective; more prone to corrosion, discoloration or staining.

-

Liquid Paints: More colour/texture variety, but less durable; may chalk, peel, fade more than a good powder coated finish.

These comparisons are discussed in literature about aluminium finish types. orangealuminum.com+2kianhuatmetal.com+2

Final Thoughts

If you’re investing in aluminium windows, doors, shopfronts or balustrades in Roodepoort or Randburg, specifying the right powder coating finish is just as important as selecting the frame design or glass type. Accend Aluminium & Glass ensures that you have access to quality powder coating/services, multiple colour and finish options, and proven durability.